Elevate your product vision to reality, where form meets function, and quality knows no compromise.

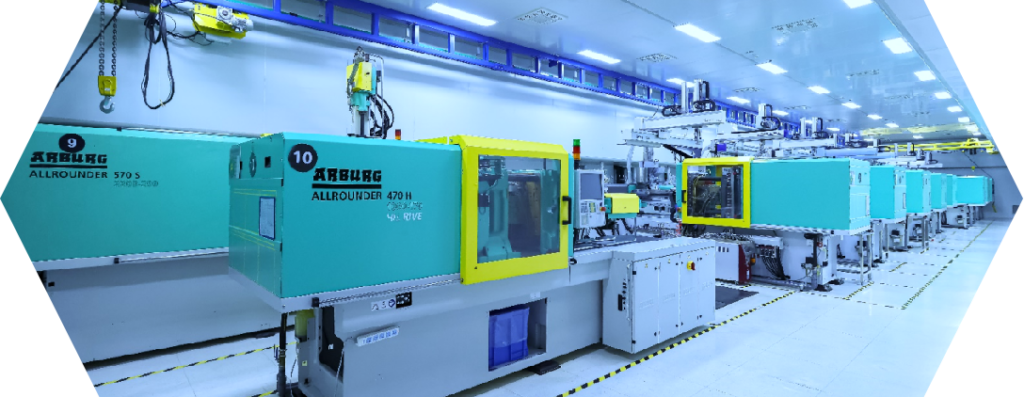

In our large, modern machinery park, alongside our in-house mold-making center, we take pride in our 2000 m² ISO 7/8 class clean room, which is equipped with 18 Arburg injection molding machines, ranging from 100 – 230 tons in clamping force for plastic and CIM/MIM injection molding. It servces as a facility for testing complete system integration. Furthermore, we offer FAT and Mold validation testing, in addition to providing contract manufacturing services to our valued customers.

Our commitment to excellence extends beyond traditional injection molding, as our clean room facilities adhere to the highest industry standards. With ISO 7/8 certification, we provide a controlled and contamination-free environment that is ideal for producing highly sensitive and critical components for industries such as medical- and laboratory technique, cosmetics, food packaging etc.

Our Arburg injection molding machines, renowned for their reliability and precision, empower us to meet the most demanding specifications and tight tolerances, ensuring that your products consistently meet the highest standards.

Our experience extends to a spectrum of advanced molding techniques, including insert molding, over-molding, and multi-component molding. With a deep understanding of these intricate processes, we have honed our expertise to offer innovative solutions that integrate components seamlessly, enhance product performance, and meet the demands of complex projects. Our proficiency in these specialized molding methods underscores our commitment to delivering exceptional, tailored solutions that push the boundaries of what’s possible in manufacturing.

When you choose Vivoid, you gain a partner that understands the critical importance of quality, cleanliness, and precision. With a focus on cutting-edge technology, a high level of automation and a team of experienced professionals, we are equipped to turn your concepts into reality, whether it’s for prototyping, small-batch production, or large-scale manufacturing.

In addition to our Arburg injection machines, we have an extensive range of auxiliary equipment at our disposal, allowing us to manufacture a wide variety of products with diverse materials and unique specifications. This comprehensive suite of auxiliary machinery enhances our production capabilities, enabling us to meet the specific requirements of a broad spectrum of products and materials. Whether it’s precision engineering, diverse material types, or specialized manufacturing needs, we have the tools and expertise to deliver exceptional results.

Our machine list for reference:

Motan from Germany

STAR GX-500V

HUSKY Altanium Neo2 (12 P.)

HUSKY Altanium Neo2 (24 P.)

Kawata DO-20N

HB-TEMP Seires 4 HB 140 U1

Diener Beam DUO