© 2025 A Global Life Science Mold&Injection Company

Mold manufacturing

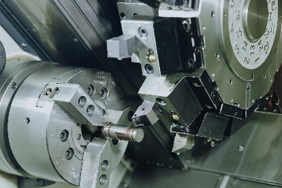

INHOUSE MOLD-MAKING

The injection mold is the heart of the entire manufacturing process, underpinning and shaping the overall success. This integral component plays a pivotal role in assuring the paramount aspects of reliable consistency, exceptional precision, top-tier quality and high cost-efficiency throughout production. It contributes to minimizing defects, reducing waste and optimizing productivity. This, in return, safeguards budget adherence and maximizes profitability.

At Vivoid, our unwavering mission and passion is to persistently exceed our clients‘ expectation through innovative solutions. Therefore, we‘ve built our state-of-the-art in-house mold-making center and continually focus on there key areas:

Maintain ongoing investments in cutting-edge technology and high automation, such as CNC machines and hot runner systems of Ewikon and Husky. We‘re proudly the most important stategic partner in China of Ewikon.

Our highly skilled and experienced technical teams are renowned for their highest degree of precision, perfection and diligence. Their motivation and passion are invaluable treasures for Vivoid.

Tailored maintenance service programms, according to the mold complexity, deliver optimum performance and prolong tool lifespan.

INNOVATION AND PRECISION IN DETAIL

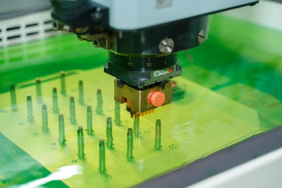

We carefully source high-quality steel and standard parts from Europe to craft pilot molds and series production molds precisely tailored to your product specifications and specific manufacturing needs.Additionally, we have our own MES(Manufacturing Execution System) to real-time monitor, control and optimize the production process, enhancing our operation excellence.In order to ensure the high precision, safety, and stablility of the products, we carry out extensive testing in the areas of materials, geometry and function during all phases of product origination. Vivoid has a inhouse measuring lab with the state-of-the-art equipments.

Our machine list for reference:

Hexagon Pioneer

Zeiss DuraMax

Mitutoyo MDH-25MB

TESA MicroHite 350

TESA MicroHite 700

Instron Instron-5940

Hexagon Optiv Classic

JSEASSON SP6-4030

Keyence LS-7030M

Mahr M300C

BYK BYK4563

YOUR ADVANTAGES WITH VIVOID

Vivoid is now an innovative pioneer in the industry. With a wealth of expertise, we specialize in crafting multi-component molds, multi-cavity molds, and modular molds with the utmost precision and innovation. Our extensive know-how and commitment to excellence ensure that we consistently deliver top-quality molds tailored to your unique requirements upon swift lead time. At Vivoid, we don’t just make molds; we master the craft.

Precision in construction, material selection and production method details wields a substantial impact on the quality of the end product through injection molding. Thus, we place greatest importance on in-depth pre-project consultation and planning. Already during the initial stages of plastic part development, we offer proposal, presenting a range of solutions, fostering creativity and promoting innovation.

Our experts possess an profound understanding of the industry’s nuances and work closely with clients to grasp their unique needs and challenges. Through comprehensive assessments, utilizing the results of warpage calculations, lessons learned and FMEAs, we develop feasibility analysis, plastic-appropriate designs and tailored production solutions to help our clients achieve the production goals, ensuring utmost precision, quality, efficiency and cost-effectiveness.

Our engineering team, equipped with cutting-edge technology, adopts digital tools to mold design and manufacturing. From intricate geometric shapes to complex multi-cavity molds with hot runner technology, they excel at bringing concepts to life. Leveraging advanced CAD/CAM software and simulation tools, they meticulously refine each aspect of the mold to ensure precision, consistently and stability in every production run.

What we have:

-Innovative Ability

–State of the art Machinery

-Hot Runner Technology

–High-Quality Steel Material

–Extensive Expertise

–Shorter Lead Time

© 2025 A Global Life Science Mold&Injection Company. Created for free using WordPress and Kubio