Safety, Stability, Reliability and Functionality

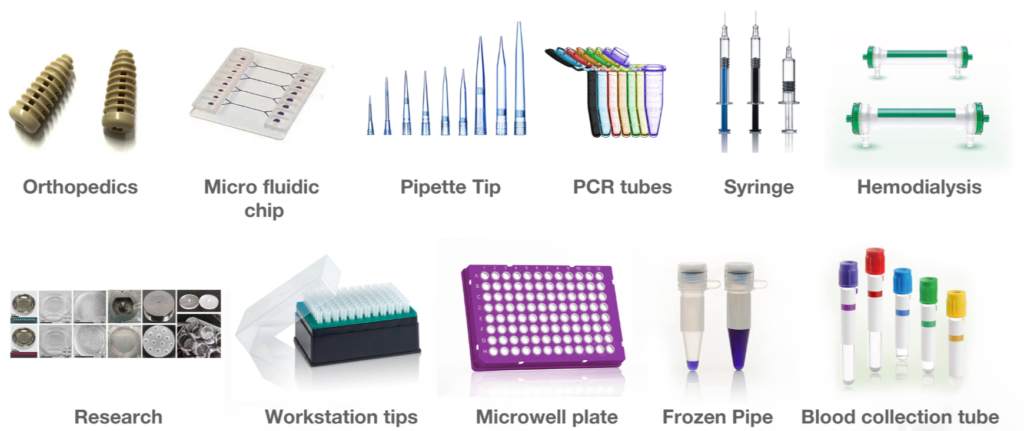

Vivoid’s primary focus is in the pharmaceutical packaging, medical & Laboratory Industries where the most strictest regulations and precision demands take precedence. We’d like to contribute to advancing healthcare and saving lives. To fulfill our mission and meet the exacting requirements of our clients, we’re not only ISO 13485 certified, but we’ve also established a 2000 m² clean room ISO 7/8 equipped with Arburg’s injection machines. These machines are renowned for their extremely high reliability and precision.

High performance Pipette Tips mold with hot runner system

Utmost Precision and Efficiency

Vivoid is a leading expert in the precision molding of pipette tips, with a strong focus on quality efficiency. In fact, as early as 2018, we already successfully created a 32-cavity mold. In 2020, we proudly showcased alongside Arburg at the Chinaplas exhibition with a remarkable 5.5-second cycle time on a 48-cavity mold. Today, our capabilities have advanced, enabling us to craft a cutting-edge 64-cavity mold equipped with a state-of-the-art hot runner system. Regardless of your specific pipette tip requirements, rest assured that we have the expertise and technology to bring your vision to life.

- Full hot runner system for stable

- The fastest cycle time < 5s

- High cavity mold experience 16- 64 cav.

- Uniform polishing process, less residue

- >96% balance control ability

- Online quick change mold structure

- Long-lasting mold life(>10M )

- Fast development cycle <15 weeks mass production

Discover pipette tips in various sizes and features to match your specific lab needs

|

Pipette tips (volume) |

Mold Cavities |

*Cycle Time (s) |

Injection Machine (kN) |

Mold Size (L/W/H)mm |

|

10~300ul (L<50mm) |

16 |

5~6.5 |

300 |

350/240/364 |

|

32 |

5~6.5 |

500 |

400/350/394 |

|

|

48 |

5~6.5 |

1000 |

400/460/430 |

|

|

64 |

5~6.5 |

1000 |

400/600/440 |

|

|

500~1250ul (L<105mm) |

16 |

6~7.5 |

500 |

350/240/394 |

|

32 |

6~7.5 |

500 |

400/350/440 |

|

|

48 |

6~7.5 |

1000 |

400/460/440 |

|

|

64 |

6~7.5 |

1000 |

400/600/498 |