Customization is a term that is increasingly mentioned by customers in today’s rapid advancement of biotechnology. The increasing complexity of instruments, reagents, experiments, etc. makes it difficult for standardized consumables to fully meet the differentiated needs of customers. On the contrary, customized high-precision supporting consumables are one of the key points to support the upgrading of medical devices and diagnostic industries at home and abroad in all aspects.

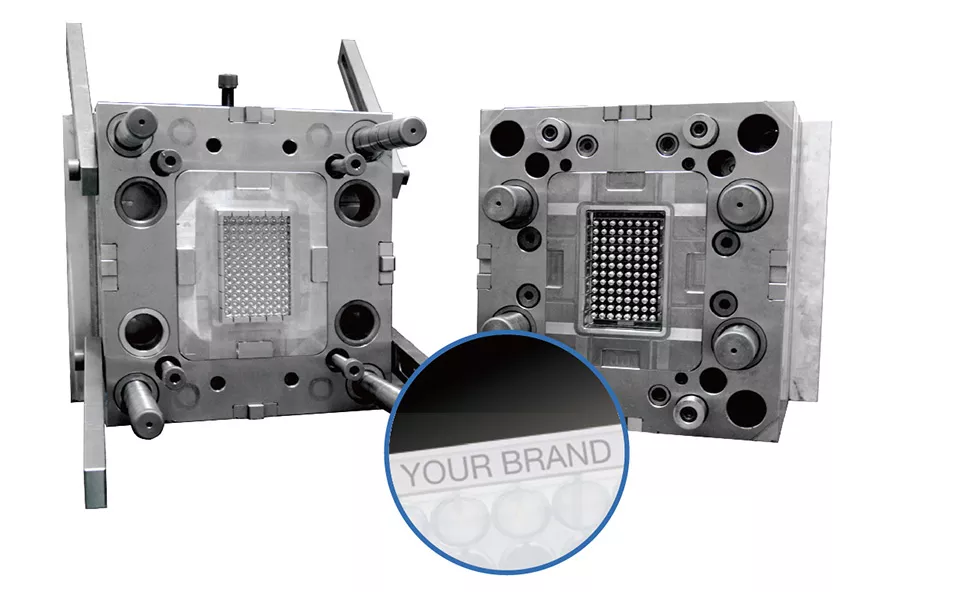

With strong mold design capability and machine tool precision machining and plastic molding capability, anchesen provides various customized services to the industry in addition to the sales of conventional products.

Since its establishment in 2019, Suzhou anchesen Bio has focused on the design, generation, and sales of high precision plastic consumables for the medical and diagnostic industries. Our plates, drip tips, tubes, and bottles are sold well in both domestic and international markets with stable quality and excellent cost performance; the nearly 1,000 square meters clean workshop jointly put into operation with Apricot in the United States is a stable design and production base for Apricot’s fully automated tips products.

What is OEM?

The customer provides the formula/order, and Ajin Bio is responsible for the generation of molds and products, and the final submission of the finished product.

What is ODM?

The customer provides the order, Agen supports the customer with tooling and product development, design and generation, and finally submits the finished product.

Years of accumulated industry experience

With a complete management team of the original Axygen design/generation line and years of experience in the industry, we have the ability to process molds and design custom products of special sizes, models and materials based on our customers’ needs.