IVC System for lab animal research

IVC systems are used to house laboratory animals, such as mice and rats, in separate ventilated cages. Each cage is equipped with its own ventilation system, which provides a controlled environment for the animals, including temperature, humidity, and air quality. IVC systems are designed to enhance animal welfare, reduce the risk of disease transmission, and improve research outcomes by providing a more controlled and hygienic housing environment for laboratory animals.

Vivoid’s outstanding engineering expertise and conscientious work ethic are now widely acknowledged across various industry sectors. We have successfully developed IVC (Individually Ventilated Cage) system with customer, the ODM project which boasts a range of advanced technical features.

Facilitate challenging scientific research with our thoughtful and forward-thinking solutions!

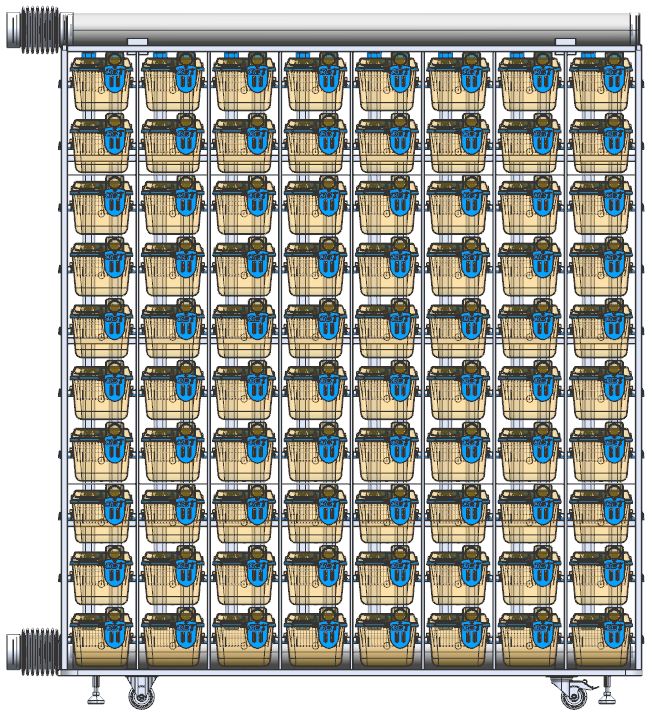

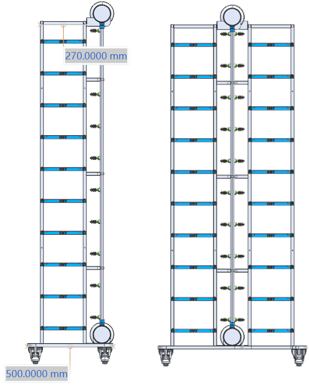

Featuring a modular design that optimizes space utilization, offering customizable dimensions and specifications to meet specific laboratory needs.

Cage frame material: SUS304 stainless steel, capable of high-pressure sterilization and easy disassembly for cleaning.

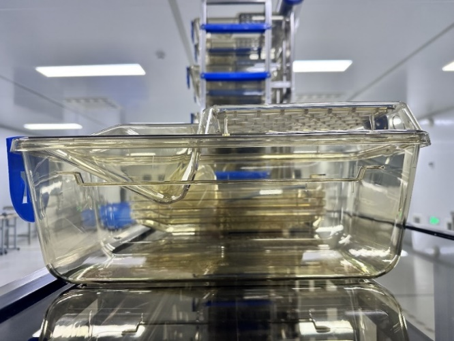

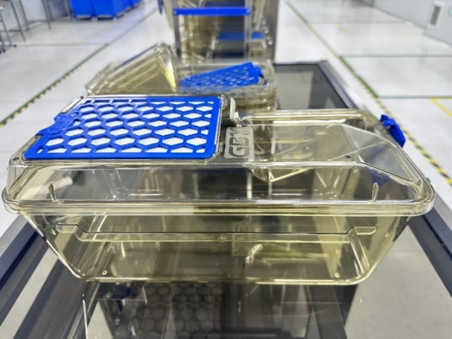

The cage box is made of high-quality, brand new PPSU material, eliminating the use of recycled or partially recycled materials. It offers excellent stability and transparency, capable of withstanding repeated high-temperature and high-pressure sterilization at 131°C for more than 300 cycles. Custom material options are available to meet various breeding scenarios.

Exhaust pipe positioned at the bottom of the cage.

After the cage box is removed or on the empty rack without installation, the unique closed-loop ventilation system, valves, and positive pressure system will automatically close the inlet and outlet, providing a double protection to prevent cross-contamination.

A unique closed-loop ventilation system, using rigid plug-in pipes in conjunction with a double-layer liquid silicone one-way ventilation valve, ensures smooth airflow within the cage box and prevents gas backflow leakage. The cage box can be easily removed and placed using guide keys, providing greater fault tolerance.

The inlet and exhaust ports of the cage box are equipped with two layers of silicone sealing rings. The first layer is a duckbill-style -way ventilation valve, and the second layer is a cross-shaped one-way ventilation valve, which automatically seals upon removal of the air tube.

The cage box utilizes lateral silicone ring sealing, ensuring that the cage box remains airtight and watertight even if subjected to external forces or placed in harsh environments. It is also easy to operate with one hand.

The cage box’s air supply port features a unique upward air supply design, ensuring that airflow moves slowly into various areas within the cage. The airflow velocity in the horizontal animal area is less than 0.1m/s.

Partition: The material used for the feed-carrying partition inside the cage box is 304 stainless steel, with a frame wire diameter of ≥3mm and a cover wire diameter of ≥2mm.

The four corners of the base feature a curved design with protruding bumper strips to protect the main structure and the cage box from impact.

The cage rack base is equipped with four corrosion-resistant/pressure-resistant swivel rubber casters, two of which have brakes, and four adjustable fixed support legs, all of which are capable of high-temperature and high-pressure sterilization.

The cage rack guide rails, fixed by specially designed stainless steel anti-dust screws and cushion washers, enhance the rack’s stability and prevent tipping.